- Homepage

- Technology

OxyCat® und SilverSan®

– Background

All common procedures for water disinfections rely on the oxidation effect of oxidants, such as chlorine, ozone and peroxide. Catalysts help increase reactivity of customary disinfectants.

OxyCat® and Oxygen

For contamination control, with an adequate catalyst, it is possible to work with natural oxygen O2. Said oxygen is then activated by the electrons of the OxyCat® catalyst.

What types of oxidation catalysts are worth considering? The answer is: group 11 catalysts. Base materials are Ag/Al2O3-fixed bed catalysts which are supplied by Johnson Matthey exclusively for SilverSan AG.

The Principle of Heterogeneous Silver Catalysis

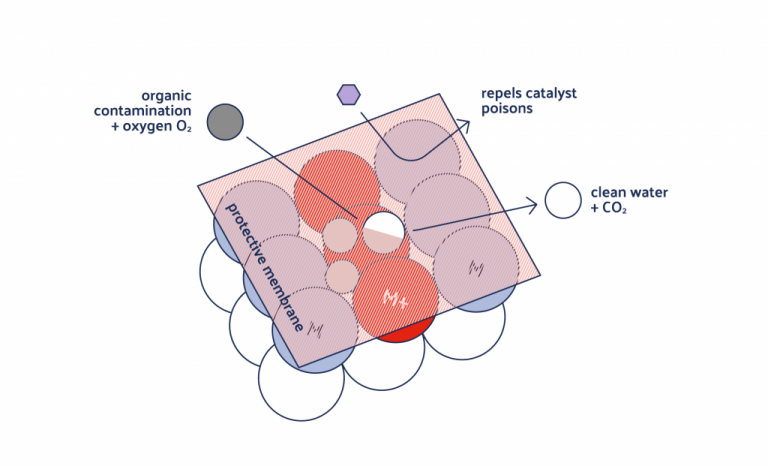

Common silver fixed bed catalysts are activated at an initial activation stage during the gas phase in the presence of NO and O2 at a few hundred degrees Celsius. During this process complex sandwich structures form on the catalyst surface. The layers of these structures are made up of on only 10 to 15 atomic layers of AgNO3 with Ag2O layers of 20 to 30 atomic mono layers underneath.

For one thing, the layers protect the silver core underneath from further oxidation. They also, however, largely determine catalytic properties. Thus, catalysts can be tailored to fit any possible application.

This technology can only be used for water treatment as long as the surface modification can be implemented and stabilized in aqueous media. PaSta AG managed to do just that with their patented SilverSan® technology.

The catalysts which we manufacture under license are sold under the name OxyCat®.

Efficacy Tests and Quality Assurance

At our production laboratory we test and maximize the effectiveness of OxyCat® products for all different kinds of applications. The final field tests and certification tests are conducted by an accredited laboratory. Together with that laboratory we developed a testing method which was even approved by the very strict United States Environmental Protection Agency (EPA).

Upon request, we also conduct final field tests for our customers at additional cost. Field tests are usually conducted over the course of 3 – 6 months.

Optimal Application and Targeted Marketing

This is how we make sure to find the right solution for every possible application. In addition, test results are crucial marketing tools. Everyone claims to provide service life of many months, or even years. But we can prove it!

If you have any questions about quality assurance and individual field testing, please contact us at: mail@pastaag.li.

Approvals

OxyCat® catalysts are production aids. They are subject to the laws and regulations pertaining to catalysts. Basic materials are manufactured by Johnson Matthey, Switzerland; exclusively for SilverSan AG. All related safety data sheets fully apply to activated OxyCat® products as well. No additional approvals required.